|

Pedestrian Walkway – Data CenterThe customer needed to minimize contamination from dirt and required an “invisible barrier” against fine dust particles, carried both by personnel foot traffic and by the movement |

|

Internal passages and accesses. Painting zoneIn this case, inside the painting section, a strong dust and dirty preventing action was needed to prevent the cross-contamination of very fine colour powders. |

|

Laboratory access. SemiconductorThis customer, in order to limit and minimize the contamination conveyed by the shoes of the operators as welle as wheels of the trolleys in the access to the laboratory instaledd multiple |

|

Internal passage between departments. Medical sectorThe customer needed to protect the passage of operators and light carts in both directions within a connecting corridor between the raw materials warehouse and a production area with controlled acc |

|

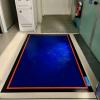

Acces to an E.P.A zone. Electronic ESDIn accessing critical E.P.A. (Electrostatic Protected Area) zones, cleaning the soles of ESD (Electrostatic Discharge) safety shoes is vital for a correct outcome of their antistatic test. |

|

Wheels cleaning and dry up. MechanicsIn this case, the customer needed to set up a barrier to the conveyed dirt, both wet and dry, in an access for electric trolleys of different sizes and capacities. |

- ‹ precedente

- 5 of 18

- seguente ›